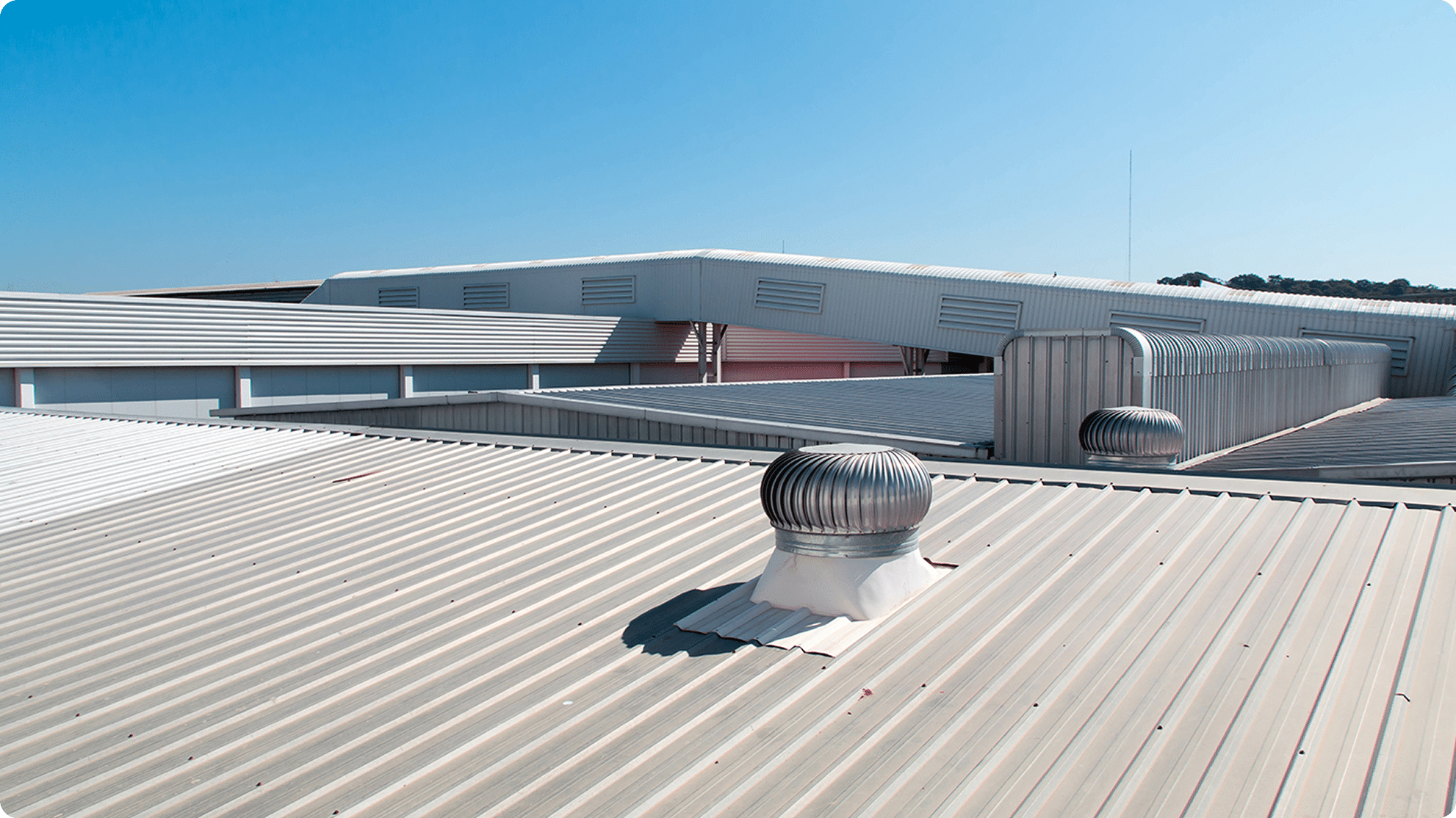

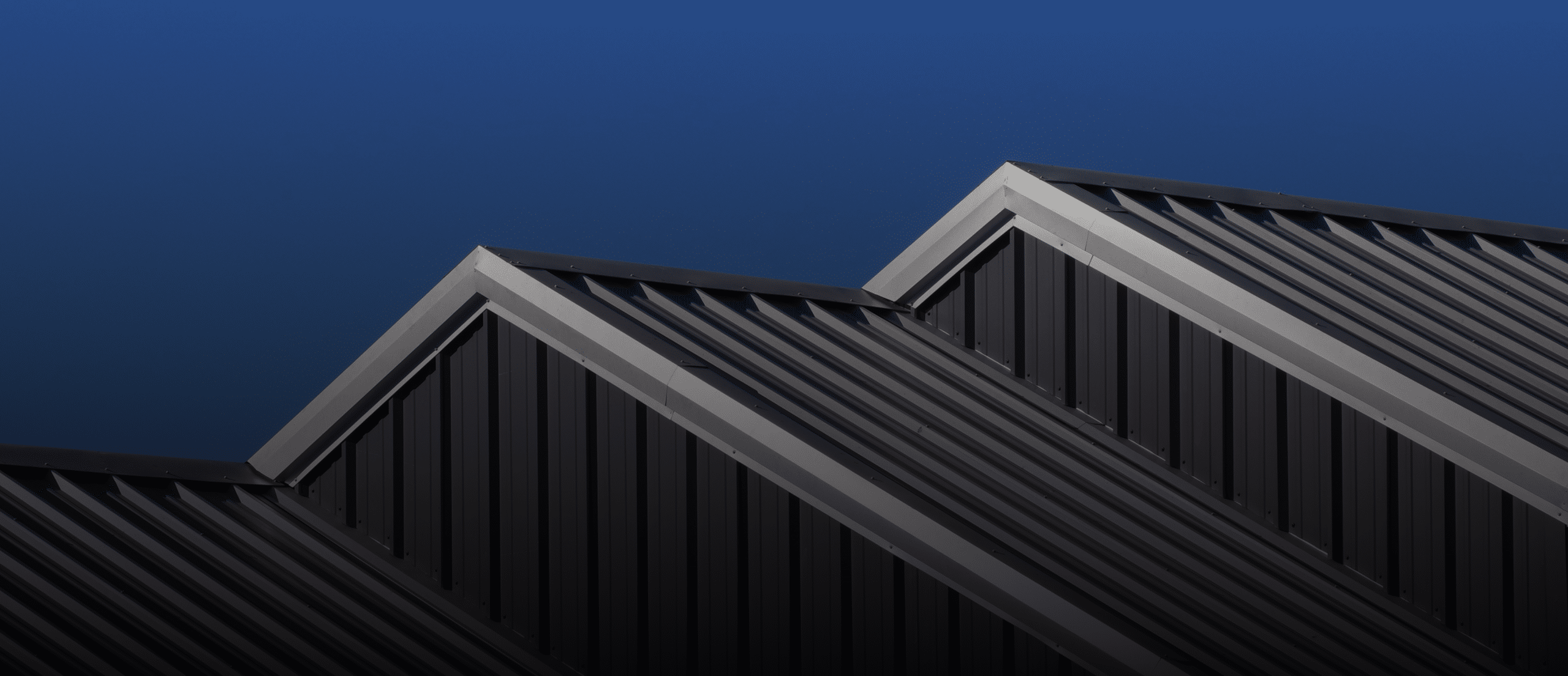

Metal roofing is also used for industrial facilities due to its strength, efficiency, and very little external upkeep it requires. It resists heavy usage, harsh weather, and environmental wear and tear while minimizing long-term expenses.

Industrial Metal Roofing & Cladding

At Renoteck, we know how extreme these conditions can get in the industrial setting. Over the years, we have experience and a reputation for excellence that have made us masters in the services of Industrial Metal Roofing and cladding solutions. From factories to warehouses to distribution centers, we undertake projects to install roofing tailored to meet heavy usage, harsh weather, and high operational demands.

Our focus is to provide durable, efficient, and cost-effective solutions that can meet the unique needs of industrial properties. We combine technical expertise with high-quality materials to ensure every project exceeds your expectations in performance and longevity. Whether upgrading your existing roof or starting a new build, Renoteck is the partner you can rely on.

Benefits of industrial metal roofing

-

100% Fire Proof

-

200 mph Wind Resistance

-

Lifetime Transferable Warranty

-

Eco Friendly (doesn’t end up in a landfill site)

-

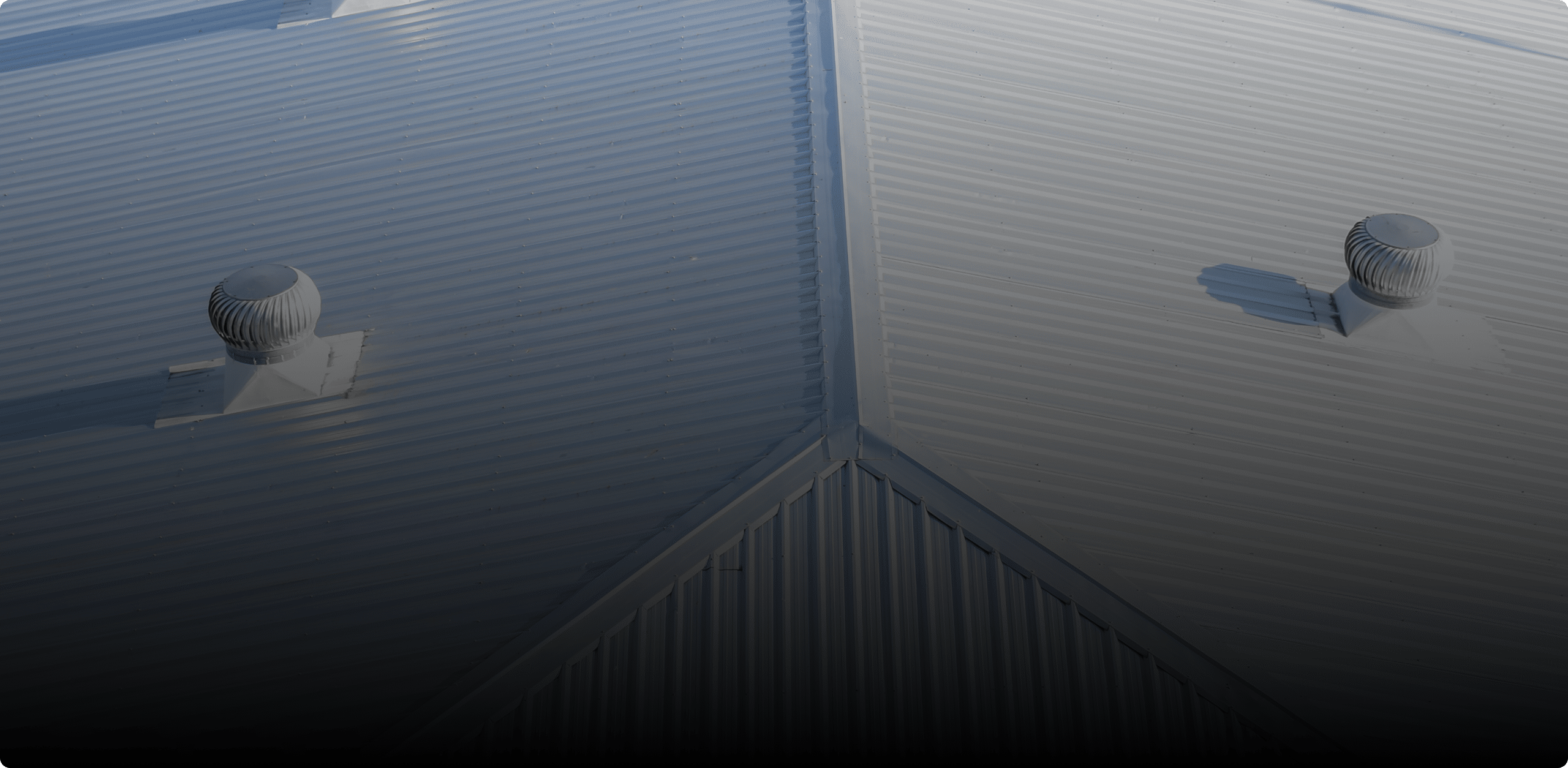

Pulls excess heat

Pulls excess heat + humidiy

-

Air circulation

Promotes good air circulation

-

Cost

Cost free operation

Our services

-

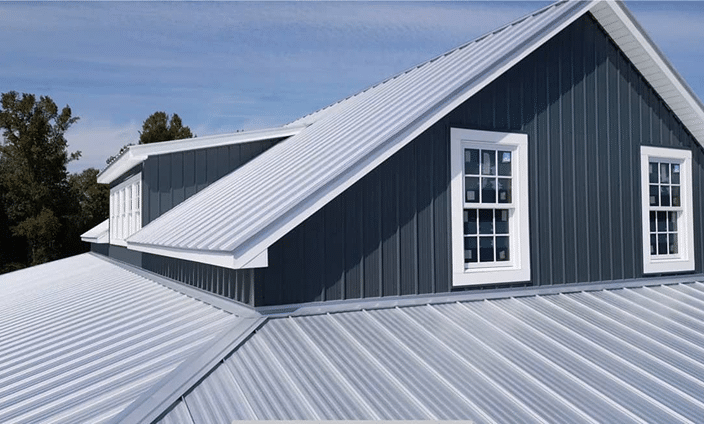

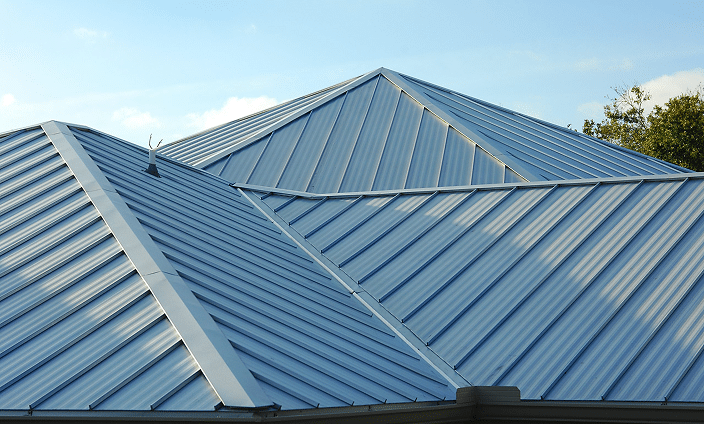

Industrial Metal Roofing

Industrial buildings need roofing systems that are strong, reliable, and efficient. At Renoteck, we design and install metal roofing solutions fabricated for the rigors of industrial applications.

Our metal roofing delivers unmatched installation for the harshest environmental conditions, including heavy snow, high winds, and strong sunlight. From standing seam systems to corrugated panels and insulated metal panels, we can provide solutions that go beyond strengthening your structure and further facilitate energy efficiency. The advantages of such facilities include lower cooling and heating costs, with very low maintenance costs, making these systems practical, long-term investments.

Whether you need a roof for a warehouse, factory, or logistics center, Renoteck’s industrial metal roofing systems deliver reliable performance you can count on.

-

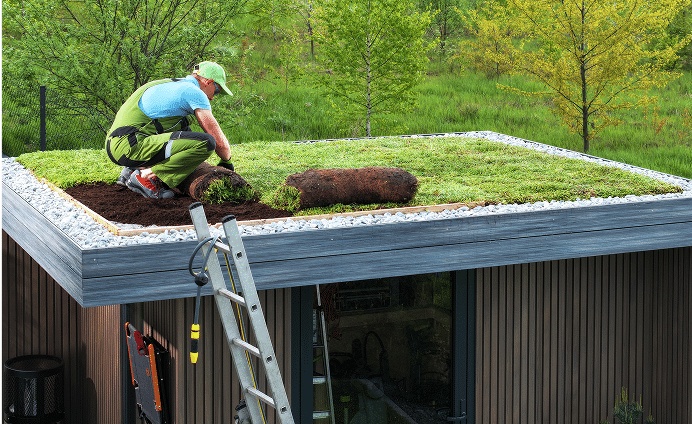

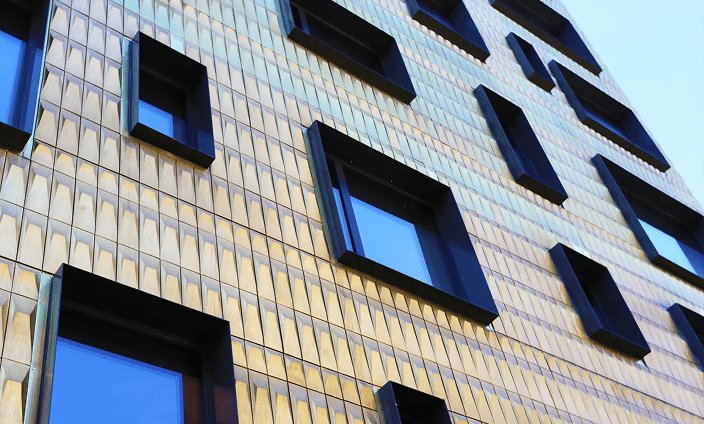

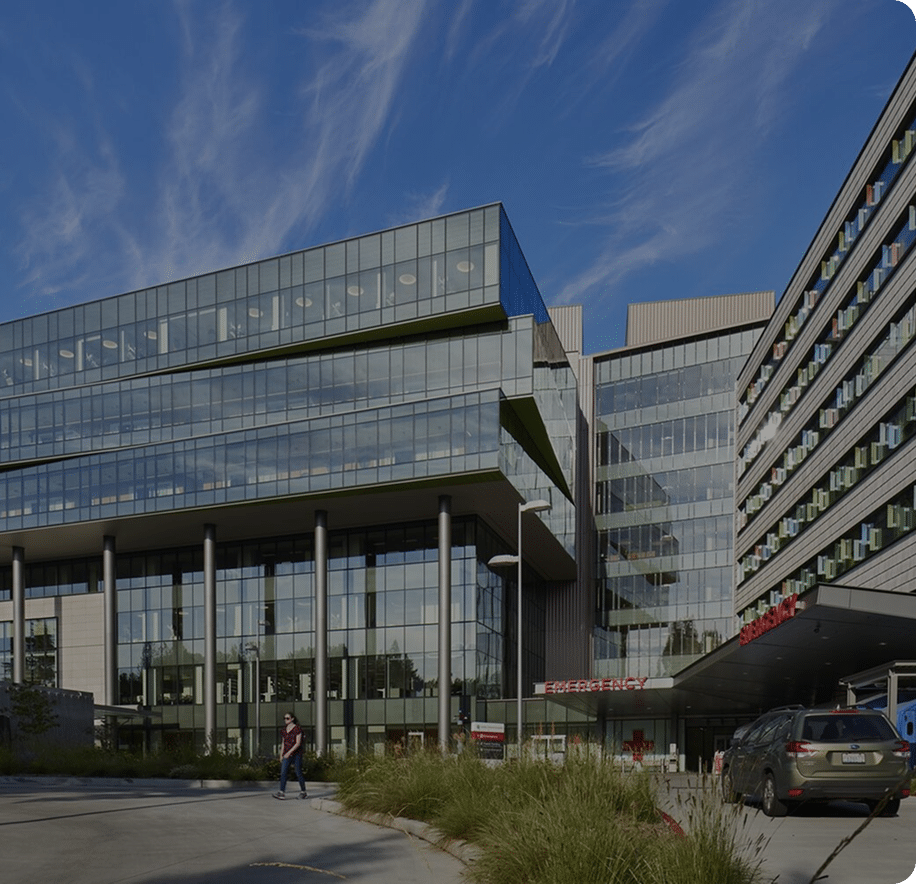

Industrial Metal Cladding

Metal cladding plays an important role in shielding the industrial building while lending great aesthetics. Renoteck’s industrial metal cladding solution is designed to offer resistance against tough environments in corrosion, impact, and extreme weather.

We can offer customized cladding systems in great material variants, including steel and aluminum, all in various finishes, to meet the peculiar needs of your facility. From increased insulation to a modern professional facade, our cladding solutions merge functionality with design.

Our team works closely with the client to develop systems that meet practical and aesthetic goals alike, so your industrial property is as efficient as it is striking.

Building types

Why customers trust Renoteck

Step-by-Step Metal Roof Installation

-

Initial Contact

Even if you’re early in the process, give us a call or drop us an email. We’re glad to help customers who are dipping their toe into the idea of metal roofing or cladding!

Provide some information about your property and we’ll start our brainstorming.1 -

Quick Response

Customer satisfaction is at the heart of everything we do. Our commitment to customers starts with a quick response to your first contact with us. Someone from our team will usually be in touch the same day. We’ll ask a few questions to make sure we understand your project and set ourselves up for success right from the beginning.

In our follow up email or phone call, we often ask for more details about things like:- Elevation on your property

- Drainage

- Unusual architectural features to consider in planning

- And, we will help you find these details if you need some guidance!

2 -

Property Inspection

A detailed property inspection is the first step in our metal roof installation process. Our team will do a thorough assessment of your site and take exact measurements, so we can plan your tailor-made roofing. For example, we will note all current features of your roof–good and bad–so we can plan the best solutions for each part of the project.

With all of this information in hand, we will discuss with you the metal roofing solution we recommend.3 -

Clear Contract

We also pride ourselves on providing clear, jargon-free contracts for our clients. You don’t want any surprises. We will provide an itemized contract for you once we have confirmed the roofing plan details with you.

The contract will describe:- The materials to be installed

- The timeline for installation

- A full cost breakdown, with no hidden fees

We’re glad to answer any questions you may have before signing on with us. From the beginning, you’ll know what to expect from our work, including a timeline you can depend on.

4 -

Full Execution

We are ready to hit the ground running, once the contract is signed. You can sit back while we manage:

- Permit applications for your metal roofing project.

- Ordering materials

- Planning and coordination of the full installation

Every part of your metal roofing project, from aesthetics, to ensuring temperature tolerance, to precise installation, gets our expert attention. We’re committed to exceptional standards in our roofing work and in our customer service.

The last step is our final detailed inspection. When you do your walkthrough of your new metal roofing installation, we want you to love what you see!5

Don’t wait for the next storm – book your free consultation today

FAQ

-

-

With proper installation and maintenance, industrial metal roofs can last 40 to 70 years or more, offering decades of reliable protection.

-

Metal roofs reflect sunlight and help reduce cooling costs during warmer months. Insulated metal panels further enhance energy efficiency by maintaining consistent interior temperatures even in large industrial spaces.

-

Yes, metal roofing is designed to handle high-impact activities, heavy machinery vibrations, and chemical or debris exposure. It’s a pretty robust option that takes care of the demands associated with the industrial environment.

-

Definitely. Metal cladding systems can be built in with insulation layers that enhance thermal performance and reduce energy loss while maintaining comfort inside.

-

Metal roofing is an environmentally friendly choice. Many systems are made from recycled materials and are fully recyclable at the end of their lifespan. Their energy efficiency also reduces a facility’s overall carbon footprint.

-

Renoteck approaches every job by first conducting a thorough assessment of the facility’s needs concerning environmental exposures, operational demands, and design preferences to ensure the final system is designed to perform and protect effectively.

-

Maintenance is minimal, typically involving annual inspections to check for loose fasteners, sealant wear, or debris buildup. Prompt attention to minor repairs can extend the life of the roof significantly.